COC Drawer-type Burn-in System

Classification:

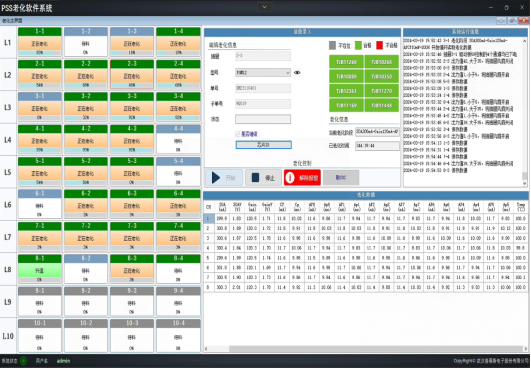

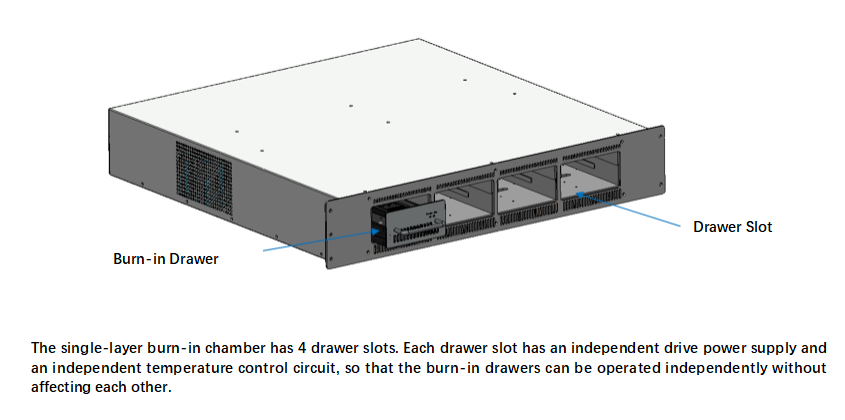

PSS COCBI Burn-in System is a high-power COC burn-in system that supports high-current, narrow-pulse power-on burn-in. It is used for long-term reliability experiments of COC chips under high temperature and stable current conditions. It supports front-light power detection, software monitoring the burn-in process data in real time and users to perform life analysis and burn-in screening on chips. The whole machine adopts a drawer-type layout, supporting up to 10 layers and 40 burn-in drawers, and the number of layers of the burn-in box can be configured according to the specific burn-in scale requirements.

- Application

- Characteristic

- Specifications

- Download

-

Application

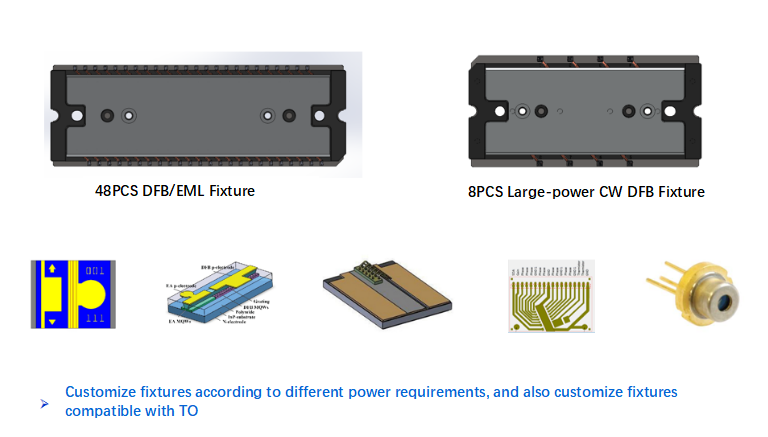

1. Burn-in and screening of COC chips of DFB, EML, and EML-SOA types

2. LD Chip reliability verification

3. LD Chip failure analysis

4. LD Chip life testFeatures

1. The temperature of each drawer controlled independently, and each drawer loaded independently with drive current, realizing multi-temperature zone, multi-variety and multi-process burn-in

2. Enhanced drive power supply, flexibly supporting DFB/EML/Tunable COC

3. Single-layer burn-in box used independently, or the burn-in scale also be increased through flexible frame combination

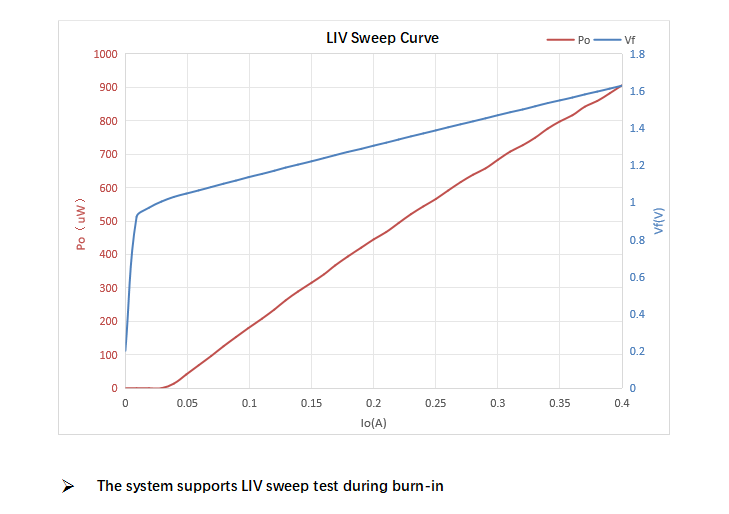

4. Support online monitoring of output power (optional)

5. Current drive direction supports software switching, supporting more types of COC wire bonding structures

6. Support N2 filling protection, support burn-in of airtight LD COC

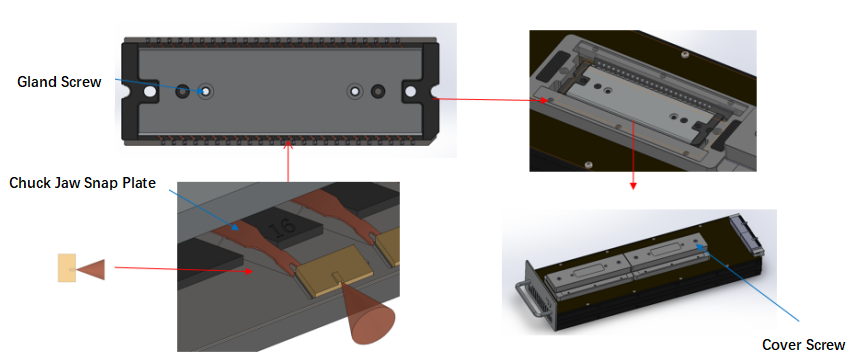

7. Fishbone fixture design, compatible with front-end patch and wire bonding processes, no manual material transfer required throughout the process

8. Drive current up to 500mA, supporting high-power laser COC burn-in

9. Complete database, supporting local database and remote server SQL database, real-time recording of data during burn-in, and supporting data curve review

10. Support customer MES system

11. Equip with an ion blower to ensure ESD safety during operation

12. UPS optional to prevent accidental power outages in the factory

13. A modular integrated design to facilitate upgrading and maintenance

14. A self-locking structure locking after power-on to prevent employees from accidentally hot-plugging

15. The specially designed COC light receiving device supports online chip wavelength testing, convenient for temperature calibration and verificationSpecification

-

1. Each drawer's temperature can be controlled independently, and each drawer can be independently loaded with drive current, enabling multi-temperature zones,

multiple varieties, and multi-process aging;

2. Enhanced drive power supply, flexibly supporting DFB/EML/Tunable COC;

3. A single-layer aging chamber can be used independently or combined with racks to increase the aging scale, offering flexible combinations;

4. Supports online monitoring of output power (optional);

5. The current drive direction supports software switching, supporting more types of COC wiring structures;

6. Supports N2 filling protection, supporting aging of airtight LD COC;

7. Fishbone-shaped fixture design, compatible with front-end chip mounting and wire bonding processes, eliminating the need for manual material transfer throughout the process;

8. Drive current up to 500mA, supporting aging of high-power laser COC;

9. A complete database, supporting local databases and remote server SQL databases, records aging data in real-time

10. process data, and supports data curve review;

11. Supports customer MES systems;

12. The system can be optionally equipped with an ion blower to ensure ESD safety during operation;

13. The system is optionally equipped with a UPS to prevent unexpected power outages in the factory;

14. The equipment adopts a modular integrated design for easy upgrading and maintenance;

15. The system has a self-locking structure that locks automatically after power-on, preventing accidental hot-swapping by employees;

16. Specially designed COC light receiving device, supporting online chip wavelength testing, facilitating temperature calibration and verification. -

Key words:

Focus on us

Tel

086-27-8990 8766