APD Integrated Burn-in system

Classification:

APD integrated burn-in system is used for reliability evaluation and burn-in screening of TO devices such as APD, APD-TIA, PIN, and PIN-TIA in the optical communication industry, and supports a single burn-in of up to 3072pcs. The system can provide 2mA constant current, 5V constant voltage and 175℃ high temperature burn-in conditions, while monitoring the VBR and TIA current of the device in real time, and automatically judge product failure. Real-time storage of monitoring data and support for tracing of burn-in and failed devices can effectively improve the efficiency and reliability of TO production, and greatly improve the output and quality of device testing.

- Application

- Characteristic

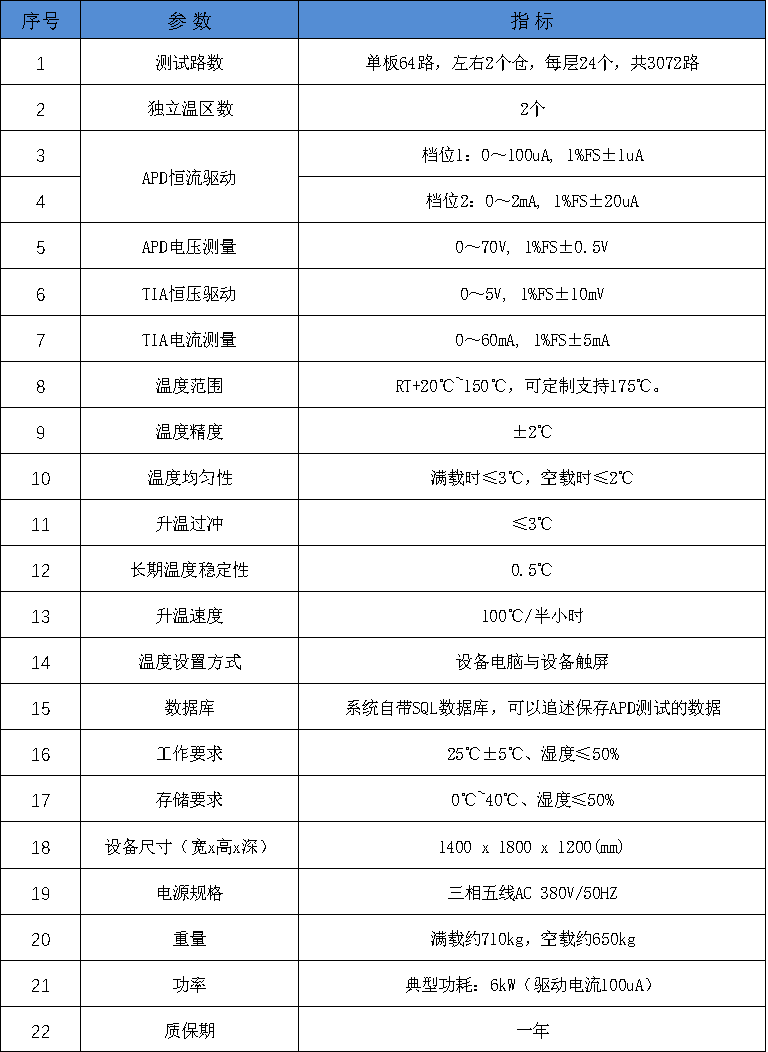

- Specifications

- Download

-

Application

1. Burn-in screening of APD, APD-TIA, PIN, and PIN-TIA TO devices in mass production

2. Long-term reliability failure test analysisFeatures

1. Provide completely independent drive current for each channel

2. APD circuit characterized by a voltage limiting protection function to prevent constant current open circuit high voltage output from damburn-in the device

3. Reliable EOS protection, TIA power-on first and then APD power-on for power-on sequence, APD power-off first & then TIA power-off for power-off sequence, and the delay configured to ensure the safety of device power-on and power-off

4. 64-channel burn-in board is used as a universal carrier to realize direct material transfer in different stations such as disk testing, burn-in and sorting, improving production efficiencySpecification

-

1. Provides completely independent drive current for each channel;

2. The APD circuit has overvoltage protection to prevent damage to the device from high voltage output when the constant current is open;

3. Reliable EOS protection, power-on sequence: TIA powers on first, then APD powers on; power-off sequence: APD powers off first, then TIA powers off. The time delay can be configured to ensure safe power-on and power-off of the device;

4. The 64-channel aging board serves as a general-purpose carrier, enabling direct material transfer between different workstations for testing, aging, and sorting, thus improving production efficiency; -

Key words:

Focus on us

Tel

086-27-8990 8766